What Sets the Langmuir Systems MR-1 CNC Gantry Mill Apart?

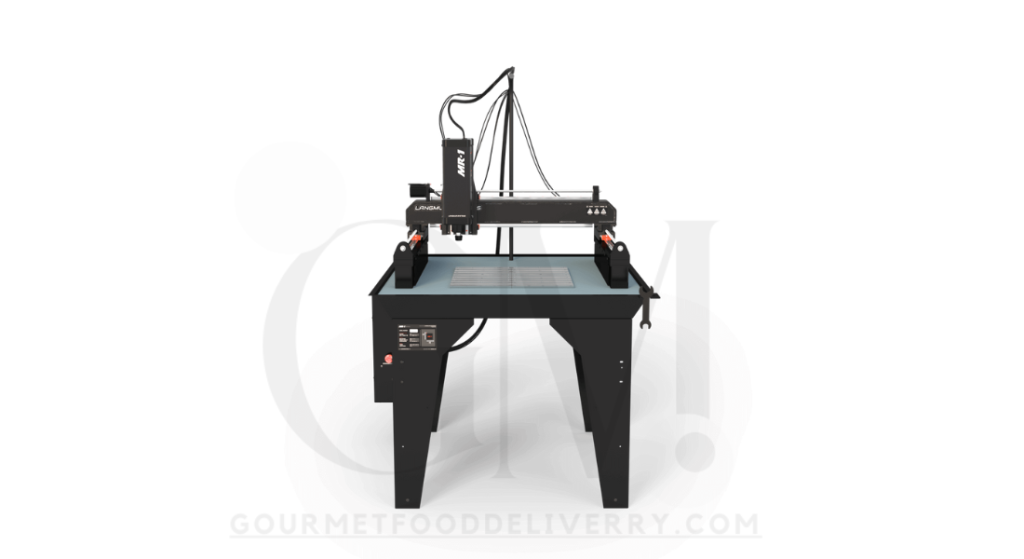

The world of precision machining is constantly evolving, and the Langmuir Systems MR-1 CNC Gantry Mill represents a leap forward in both technology and accessibility. Designed for both professional machinists and DIY enthusiasts, this CNC gantry mill offers an impressive combination of precision, power, and versatility. Whether you’re working with metals, plastics, or composites, the Langmuir Systems MR-1 CNC Gantry Mill delivers results that can take your projects to the next level.

In this article, we’ll delve deep into the features, benefits, and applications of the Langmuir Systems MR-1 CNC Gantry Mill. By the end, you’ll understand why this machine is a top choice for those seeking a high-performance milling solution.

1. Overview of the Langmuir Systems MR-1 CNC Gantry Mill

The Langmuir Systems MR-1 CNC Gantry Mill is a cutting-edge machine designed for precision milling and machining operations. It utilizes a gantry-style design, which ensures rigidity and stability even under high-speed cutting conditions. This CNC mill offers a robust set of features that makes it ideal for a wide range of industries, including aerospace, automotive, and product prototyping.

One of the key advantages of the Langmuir Systems MR-1 CNC Gantry Mill is its compact design, which allows it to fit in small spaces while still delivering industrial-grade performance. This makes it an excellent choice for small businesses, hobbyists, and anyone who needs high-quality machining capabilities in a more accessible package.

2. Key Features of the Langmuir Systems MR-1 CNC Gantry Mill

– High-Precision Performance

Precision is the cornerstone of any CNC machine, and the Langmuir Systems MR-1 CNC Gantry Mill excels in this area. Equipped with a powerful stepper motor and advanced control systems, the machine ensures tight tolerances and consistent performance. Whether you are creating detailed prototypes or machining intricate parts, this mill delivers the accuracy required for professional-grade results.

– Large Work Envelope

Despite its compact footprint, the Langmuir Systems MR-1 CNC Gantry Mill offers a generous work envelope, making it capable of handling larger projects. The machine’s work surface allows for the machining of parts that are up to 32 inches wide and 24 inches deep. This spacious work area ensures that you can tackle a wide range of projects, from small components to larger prototypes, all without the need for additional machinery.

– User-Friendly Interface

Ease of use is essential for any CNC machine, and the Langmuir Systems MR-1 CNC Gantry Mill does not disappoint. The machine comes with a user-friendly interface that simplifies the milling process. The intuitive control software allows users to set up and operate the machine with minimal effort, even if they are new to CNC machining. Whether you’re adjusting feed rates, changing tool paths, or performing diagnostic checks, the software makes these tasks quick and straightforward.

– Durable and Sturdy Construction

The Langmuir Systems MR-1 CNC Gantry Mill is built to last. Constructed with high-quality materials, including anodized aluminum and precision steel components, this machine can handle tough workloads without compromising its integrity. Whether you are machining soft materials like plastic or more rigid materials such as steel, the Langmuir Systems MR-1 CNC Gantry Mill provides the durability and reliability required for consistent performance.

– Customizable Tooling Options

Another standout feature of the Langmuir Systems MR-1 CNC Gantry Mill is its flexibility in tooling. This CNC mill is compatible with a variety of cutting tools, allowing users to tailor their milling process to meet the specific demands of each project. From end mills and drills to custom tooling, the Langmuir Systems MR-1 CNC Gantry Mill can accommodate various applications, making it a versatile solution for a wide range of machining needs.

– Modular Design for Easy Upgrades

The modular design of the Langmuir Systems MR-1 CNC Gantry Mill allows for easy upgrades and customization. As your machining needs evolve, you can add new features or replace components to ensure the machine continues to meet your requirements. This modular approach provides users with the flexibility to grow their capabilities without having to purchase a completely new machine.

3. Advantages of the Langmuir Systems MR-1 CNC Gantry Mill

– Cost-Effective Solution for Precision Machining

One of the biggest advantages of the Langmuir Systems MR-1 CNC Gantry Mill is its cost-effectiveness. While many CNC mills on the market can be prohibitively expensive, the Langmuir Systems MR-1 CNC Gantry Mill is priced competitively, making it accessible to small businesses and hobbyists without sacrificing performance. The affordable price point combined with its high-quality construction makes it an excellent investment for anyone looking to expand their machining capabilities.

– Faster Production and Increased Efficiency

Thanks to its advanced CNC technology and automation, the Langmuir Systems MR-1 CNC Gantry Mill enables faster production times and higher throughput. This means you can produce more parts in less time, improving overall efficiency. The automation features of the machine help reduce the likelihood of human error, ensuring that each part meets the required specifications without the need for constant supervision.

– Ideal for Small-Batch Production and Prototyping

The Langmuir Systems MR-1 CNC Gantry Mill is perfect for small-batch production and prototyping. Its versatility in handling different materials and custom tools makes it an ideal choice for businesses that need to produce small quantities of high-quality parts. Whether you’re developing prototypes for a new product or creating low-volume production runs, this machine delivers the precision and reliability you need to bring your designs to life.

– Minimal Setup and Maintenance

Unlike other CNC machines that require extensive setup and regular maintenance, the Langmuir Systems MR-1 CNC Gantry Mill is designed for ease of use. Setting up the machine is quick and easy, and the maintenance requirements are minimal. With proper care and routine checks, the machine can run smoothly for years without requiring significant downtime.

4. Applications of the Langmuir Systems MR-1 CNC Gantry Mill

The Langmuir Systems MR-1 CNC Gantry Mill is a versatile machine that can be used in a wide range of applications across various industries. Some of the most common uses include:

– Product Prototyping

In the world of product development, prototyping is essential for testing ideas and designs before mass production. The Langmuir Systems MR-1 CNC Gantry Mill is an ideal tool for creating high-precision prototypes. Whether you’re working on consumer electronics, automotive components, or medical devices, the mill provides the accuracy required for functional prototypes.

– Custom Parts and Components

Businesses that specialize in custom parts and components will benefit greatly from the Langmuir Systems MR-1 CNC Gantry Mill. Its ability to work with a wide range of materials and produce intricate designs makes it perfect for creating parts that are tailored to specific requirements. From brackets and housings to more complex mechanical components, this machine delivers the flexibility and precision needed for custom manufacturing.

– Tooling and Fixtures

The Langmuir Systems MR-1 CNC Gantry Mill is also commonly used to create tooling and fixtures for other machines. This can include jigs, clamps, and other tools that help improve the accuracy and efficiency of machining operations. The mill’s precision ensures that tooling and fixtures are made to exact specifications, improving overall production quality.

– Small-Batch Production

Many businesses require small batches of parts, particularly when testing new designs or fulfilling limited orders. The Langmuir Systems MR-1 CNC Gantry Mill is well-suited for this type of production. Its efficiency, combined with the ability to produce high-quality parts, makes it an excellent choice for small-scale manufacturing needs.

5. How to Get Started with the Langmuir Systems MR-1 CNC Gantry Mill

Getting started with the Langmuir Systems MR-1 CNC Gantry Mill is easy. Here’s a step-by-step guide to help you set up and start using the machine:

– Step 1: Setup

Unbox and assemble the mill according to the included instructions. Ensure that all components are securely connected and that the machine is placed on a stable surface. Double-check the wiring and connections to avoid any issues during operation.

– Step 2: Install Software

Install the software that comes with the Langmuir Systems MR-1 CNC Gantry Mill. The software interface will guide you through the process of setting up your first project and making adjustments to the machine settings.

– Step 3: Choose Materials and Tools

Select the material you want to machine and install the appropriate cutting tools. Make sure the tools are secure and properly aligned for optimal cutting performance.

– Step 4: Program the Machine

Use the software to program the machine with the specifications of your project. Input details such as feed rates, cutting depths, and tool paths to ensure the mill operates according to your design.

– Step 5: Begin Machining

Start the machining process and monitor the operation to ensure everything runs smoothly. Make any necessary adjustments along the way, and be prepared to stop the machine if any issues arise.

Conclusion: Is the Langmuir Systems MR-1 CNC Gantry Mill Right for You?

The Langmuir Systems MR-1 CNC Gantry Mill is a highly versatile, precise, and affordable machine that offers a range of benefits for professionals and hobbyists alike. Whether you’re looking to improve your workshop’s capabilities or start a small-scale production business, this CNC mill offers the precision, efficiency, and durability you need.

By incorporating the Langmuir Systems MR-1 CNC Gantry Mill into your operations, you can improve your machining workflow, expand your capabilities, and achieve the high-quality results required for success in today’s competitive market.